Unlocking Efficient Warehousing: Introducing Storlogi’s Shuttle Racking System

26Storlogi Shuttle Racking System Leader in Intelligent Warehouse Solutions ,High - density Storage ,Automated Operation /,Modular Design

View detailsSearch the whole station

Are you frustrated by the low efficiency of manual handling and constant delays in order delivery? Are you sighing helplessly at the limited warehousing space, the chaotic piling of materials, and the difficulty in finding and retrieving goods? Are you bearing the heavy operational pressure caused by frequent equipment failures and high maintenance costs? No more! Storlogi brings a professional solution – the belt conveyor line, to break through all your warehousing and logistics challenges one by one!

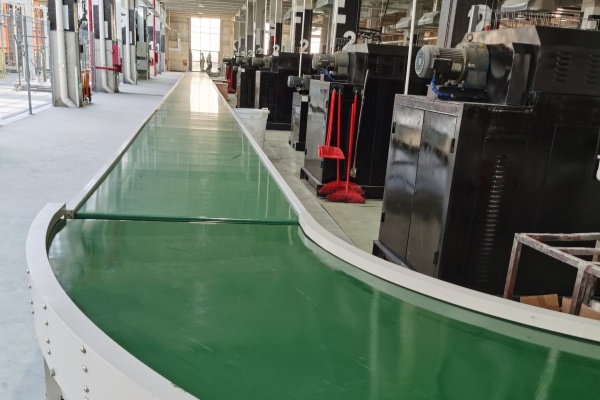

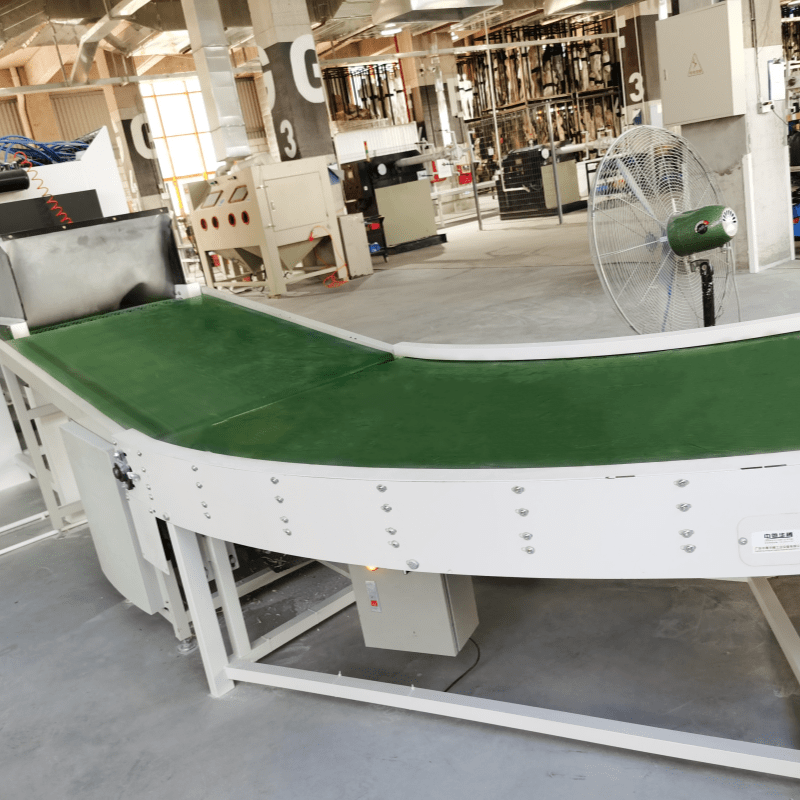

Storlogi’s belt conveyor line is specifically designed to address the pain points in warehousing and logistics! With its outstanding features of high efficiency, stability, flexibility, and precise adaptation, it becomes your indispensable assistant in warehousing operations. The continuous material transportation at a uniform and stable speed is like an unstoppable “material highway,” skyrocketing your production efficiency. Moreover, we understand that the warehousing needs of different enterprises vary greatly. Therefore, whether it’s a straight, curved, or inclined belt conveyor line, we can customize it according to your actual scenario to ensure that every inch of space is fully utilized and every material handling requirement is met.

In terms of straight belt conveyor lines, their simple design enables rapid transportation of large quantities of materials over long distances, suitable for material allocation between different areas within a warehouse, greatly improving material flow efficiency. Curved belt conveyor lines cleverly solve the problem of irregular warehouse layouts, allowing materials to turn flexibly within a limited space and avoiding logistics blockages caused by space constraints. Inclined belt conveyor lines are tailor-made for warehousing sites with height differences. With their powerful drive systems and stable operating performance, they ensure that materials can be easily and safely transported to the designated height, meeting diverse warehousing operation needs.

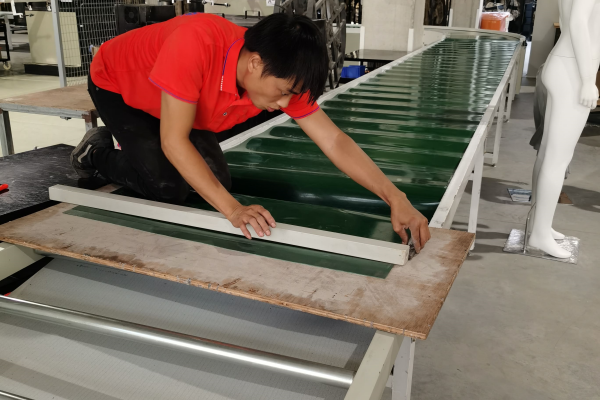

Are you worried that the equipment is complex, and maintenance will be time-consuming, labor-intensive, and costly? Storlogi’s belt conveyor line will completely dispel these concerns! It is manufactured using high-quality materials and exquisite craftsmanship, with a simple and clear structure. Daily maintenance is easy to handle, and even employees without professional skills can quickly master it.

In terms of materials, the belts we select have high strength, wear resistance, and corrosion resistance, capable of withstanding long-term, high-intensity operation and reducing downtime for maintenance due to belt damage. As a key component supporting the belt’s operation, the rollers are made of high-quality materials and manufactured using advanced processes. They rotate flexibly and have good wear resistance, greatly reducing operating resistance and improving conveying efficiency.

Moreover, its stable performance results in an extremely low failure rate, significantly reducing maintenance costs and downtime. This allows you to effectively control operating costs and truly achieve cost-effectiveness. At the same time, we also provide a comprehensive after-sales service system. Our professional after-sales team is always available to solve any problems you encounter during equipment use, leaving you with no worries.

Drive – in racking, with its unique concept of green storage, is triggering a revolution in the warehousing industry. By maximizing the use of storage space, reducing resource waste, and lowering energy consumption in operating costs, drive – in racking not only meets enterprises’ needs for efficient warehousing but also aligns with the current society’s pursuit of green and sustainable development. This storage solution that combines efficiency and environmental protection is gradually becoming a key tool for enterprises to achieve green warehousing and promote sustainable development.

Drive – in racking achieves green warehousing mainly through the following approaches: Firstly, with its compact layout design, it eliminates or significantly reduces the aisle space between traditional racks, enabling every square meter of space to be fully utilized. This effectively reduces the occupation of land resources. Secondly, the First – In – First – Out (FIFO) or Last – In – First – Out (LIFO) storage methods of drive – in racking ensure the orderly management and rapid circulation of goods, reducing inventory backlog and expiration losses, and further saving resources. Moreover, this racking design simplifies the warehousing operation process, reducing the reliance on manpower and energy, and thus reducing carbon emissions during operation. In conclusion, drive – in racking, with its scientific layout, efficient storage methods, and environmentally – friendly operation concept, provides strong support for enterprises’ green warehousing transformation.

The reason why Storlogi’s belt conveyor line can become a powerful tool to solve warehousing and logistics problems lies in its scientific and rigorous design principles. From the material selection of the belt to the layout design of the rollers, from the precise control of the tensioning device to the optimized matching of the motor drive system, every detail is carefully crafted, and every design aims to achieve the most stable and efficient material transportation.

In belt material selection, we have conducted a large number of experiments and comparisons to select the most suitable belt material for the warehousing and logistics environment, ensuring its good performance under various working conditions. The layout design of the rollers is precisely calculated based on the belt’s operating speed and load-bearing capacity. Reasonable spacing and quantity ensure the smooth operation of the belt, reducing deviation and bouncing phenomena.

The tensioning device adopts advanced automatic tensioning technology, which can automatically adjust the tensioning force according to the tightness of the belt, ensuring that the belt is always in the best working condition and extending its service life. The motor drive system selects high-efficiency and energy-saving motors and is equipped with an intelligent speed regulation device. It can precisely adjust the motor’s speed according to the material conveying volume and transportation distance, achieving flexible control of the conveying speed and improving energy utilization efficiency.

We know that only by paying attention to every detail can we bring you a truly worry-free warehousing and logistics experience. Storlogi always adheres to a customer-centric approach, continuously pursuing the quality and performance of its products, and providing the most reliable guarantee for your warehousing and logistics.

Don’t let warehousing and logistics problems become stumbling blocks for your enterprise’s development! Immediately choose Storlogi’s belt conveyor line, and let’s break through the difficulties together to usher in a new era of efficient and smooth warehousing!

Storlogi Shuttle Racking System Leader in Intelligent Warehouse Solutions ,High - density Storage ,Automated Operation /,Modular Design

View detailsStorlogi Cantilever Racking features adjustable arms for efficient storage of pipes, beams, and irregular items, boosting warehouse productivity by 30%.Maximize warehouse space with multi-layer cantilever design – increase storage capacity by 50% ...

View detailsDrive-in racks are powerful assistants for optimizing warehouse space. They can achieve high-density storage, allowing forklifts to directly enter the interior of the racks for storing and retrieving goods. They are suitable for storing a large qu...

View detailsShelving technology plays a crucial role in the digital transformation of warehousing. Storlogi provides advanced solutions such as intelligent shelving and automated stereoscopic warehouses, integrating Internet of Things and big data technologie...

View details 0

0loading...