I. Exceptional Load-Bearing Capacity for Versatile Storage Needs

1. Simple Structure & Reliable Safety

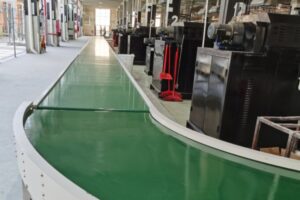

Beam racking consists of core components like column frames (uprights) and beams, featuring a straightforward design. The boltless modular construction prevents loosening, ensuring overall stability and robust load-bearing capacity. Column protectors are typically added to shield against forklift impacts, further enhancing safety.

2. Flexible Height Adaptability

Individual columns can reach heights of 12 meters or more, adjustable to fit warehouse ceilings. This vertical flexibility maximizes storage density by utilizing unused overhead space.

3. Easy Adjustability & Modular Combinations

Beams can be adjusted vertically in 75mm or 50mm increments, allowing flexible layer heights and configurations. Modular combinations enable unlimited layout adjustments, with no restrictions on item retrieval order.

II. Design Principles

1.Optimized Space Utilization

By adjusting beam heights and spans, the racking can accommodate various pallet sizes, maximizing warehouse space efficiency. Additionally, configurations can be tailored to fit warehouse layouts, further enhancing spatial utilization.

2.Modular Design

The racking system employs modular components for easy assembly and disassembly. This design not only reduces transportation and installation costs but also allows flexible adjustments to meet specific customer requirements.

3.High-Strength Materials

Primary load-bearing components such as uprights and beams are constructed from high-strength steel, ensuring stability and durability. These materials also offer excellent corrosion resistance, extending the shelf’s service life.

III. Economic Benefits for Clients

1.Reduced Warehouse Costs

Beam racking significantly lowers warehouse costs by improving space utilization and streamlining operational workflows. Additionally, high-quality racks offer extended service life and low maintenance requirements, further reducing long-term investment costs.

2.Enhanced Operational Efficiency

The standardized, modular design of the racks enables seamless inventory access and retrieval. When paired with automated equipment like forklifts and stackers, this system boosts both efficiency and accuracy, helping businesses reduce delivery cycles, enhance customer satisfaction, and strengthen market competitiveness.

3.Strengthened Market Position

By improving warehouse efficiency, operational accuracy, and cost management through intelligent systems, beam racking empowers companies to gain a competitive edge. These advantages enable businesses to secure more market share and customer trust in fiercely competitive industries.

In a rapidly evolving world, Storlogi beam racking is emerging as the preferred choice for modern businesses—thanks to its exceptional load-bearing capacity, flexible spatial layouts, intelligent management systems, and sustainable warehousing concepts.

Choose Storlogi, and together, let’s “Smart Storage for the Future, Build a Brighter Tomorrow!” Transform every inch of space into intelligent, dynamic storage and rewrite the future of warehouse management—together!

StorLogi

StorLogi